The Future of Aerospace Assembly

10 weeks project, Fall 2018, MFA Umeå Insitute of Design

Individual project

—

In collaboration with

Challenge

The project outline was to explore and design new solutions for the next generation of aerospace assembly, in collaboration with Atlas Copco. I decided to focus on improving the solid riveting process which is an old method of joining material together. Solid rivets are one of the most reliable, strongest, and cheapest fasteners today and are therefore still used in many different industries today and especially within the aerospace assembly.

Approach

Riveting is a difficult process that requires professional riveters with long experience in the industry. From the research, I found out that being a riveter is a special “feeling” you need to have which you get from time and mistakes. Therefore I wanted to look into “how might we reduce the long learning process of becoming a riveter?”

SENSE

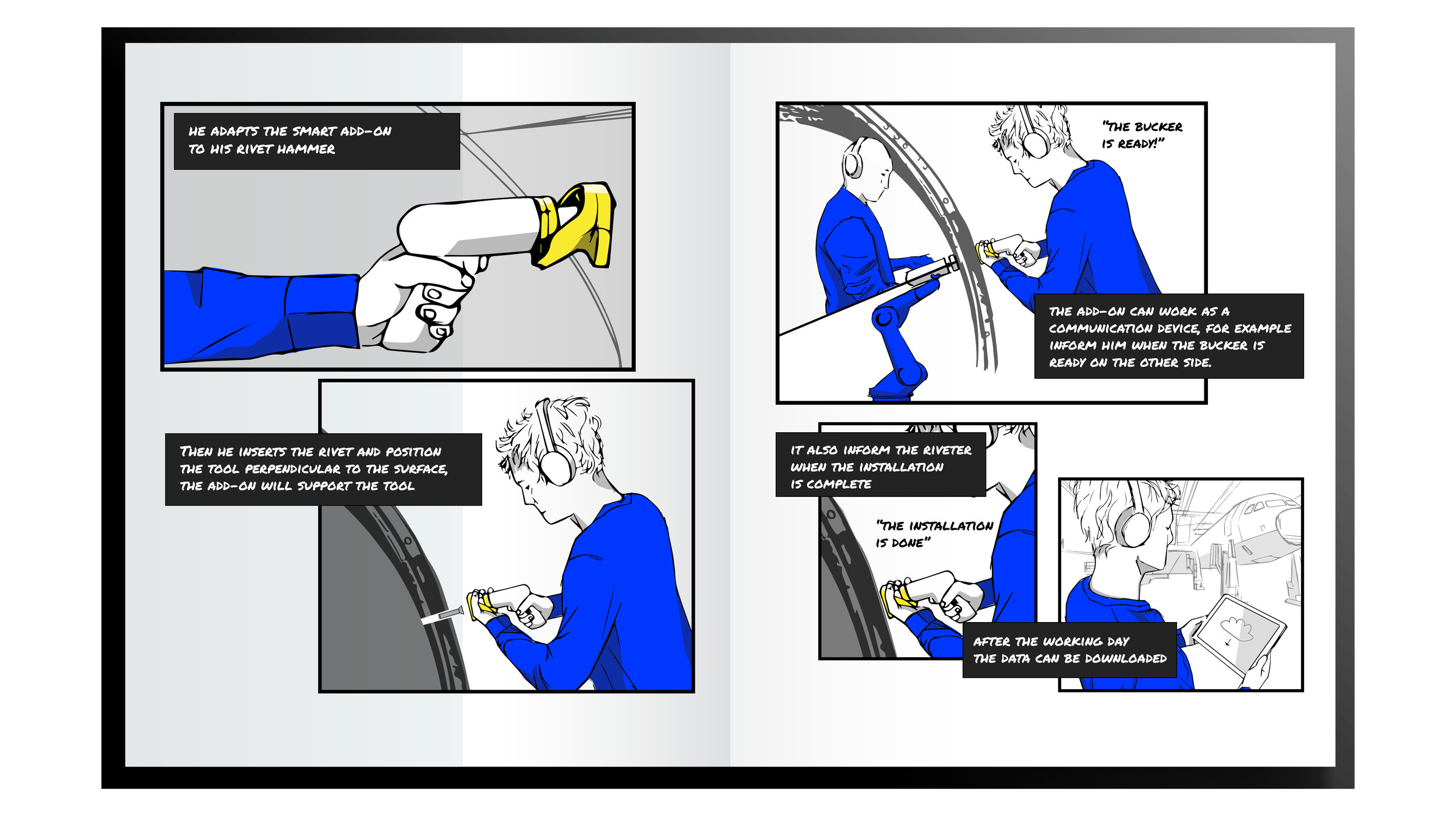

The result of the project is an intelligent riveting add-on that can be attached to the already existing riveting hammers and becomes an extra grip handle during use. Sense is connected to a smart system that measures sound and vibrations in both the tool and the joining materials to guide the operators during the riveting process. The focus is to reduce the long learning process of becoming a riveter by improving the human senses and experiences with technology.

Beter stabilisation & feedback

Sense work as an extra grip handle during the riveting. The ergonomic grip also gives the operator better stabilization and feedback against the working surface without damaging the surface. The extra-grip handle will also reduce some vibrations for the operator’s hand due to vibration damping materials and a bigger distance between the tool and hand.

Consists of two parts

Sense consists of two parts, the Sense Body, which is the main part of the product, and the Sense Attachment Ring, which is attached to the rivet hammer. The Attachment Ring is pre-mounted on the rivet hammer and attached to the Sense Body through an easy "click to lock" system. Underneath there is a button for easy release. Atlas Copco has several different types of riveting hammers that come in different sizes, therefore the attachment ring can be changed depending on what rivet hammer is being used.

Operator Guidance

After pressing the start button on the top, a white light shows that Sense is active. The rivet hammer can then be pushed forward to start the safety trigger. When the rivet hammer starts a pulsing light will be shown that data is calculating. When the installation is complete a green light will be shown.

Active

Moving

Working

Installation Complete

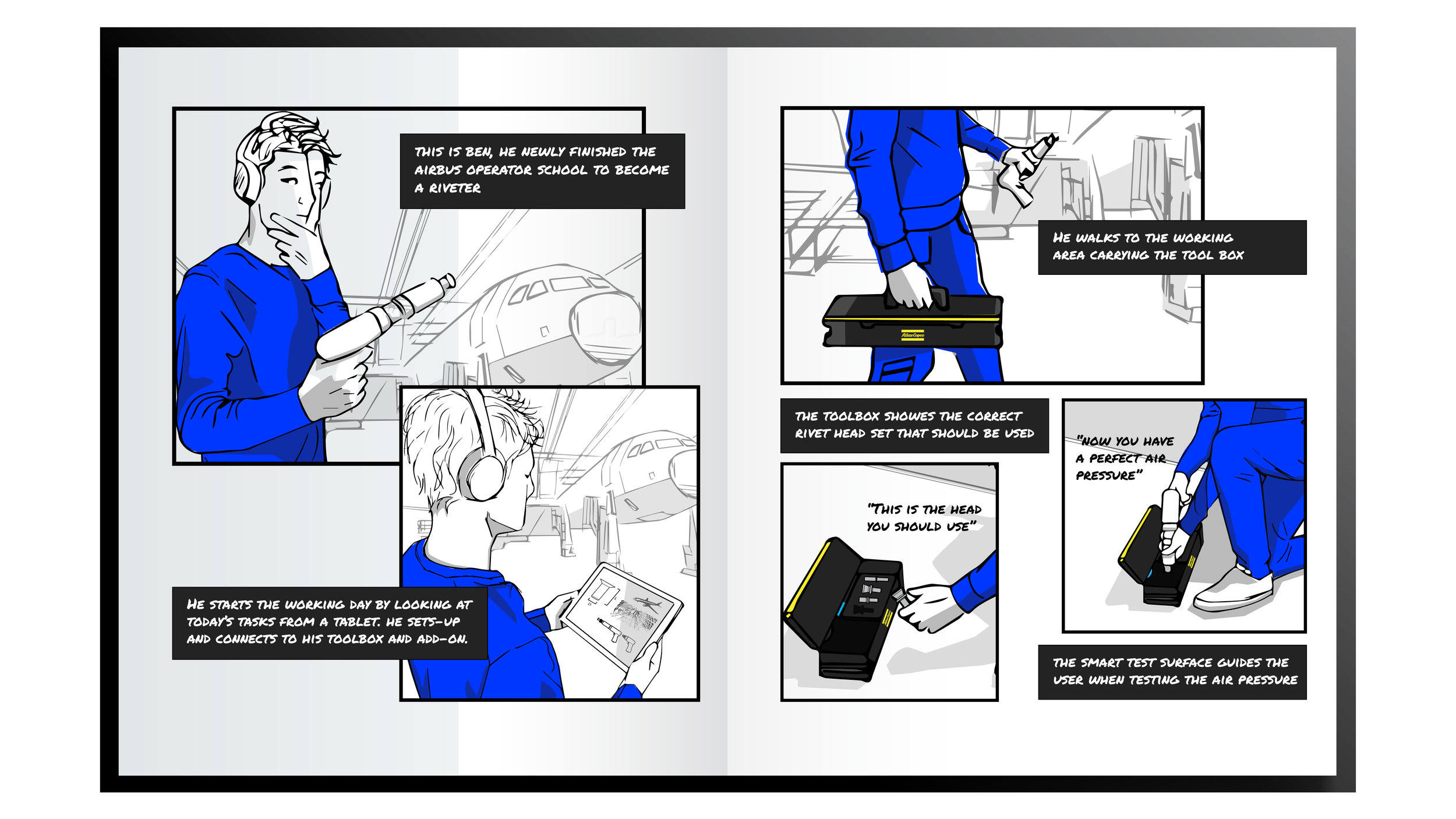

Concept Scenario

Research

Field trip to Airbus (Hamburg) & Atlas Copco headquarters in Stockholm

The project kicked off with a 3 days field trip starting with the Airbus production site to see the assembly process in Hamburg, Germany. On the second day, we had an interview session with an engineering expert at Airbus, followed by a visit to Atlas Copco headquarters in Nacka, Stockholm.

Atlas Copco

The Atlas Copco Group is a global industrial group of companies headquartered in Nacka, Sweden. The company is the leading supplier of industrial power tools and assembly systems to the manufacturing industry. Atlas Copco has a wide range of products within each step of the aerospace assembly.

Analysis

Sharing findings within the class

Brainstorm sessions & identifying opportunity areas

Role playing of early developed ideas

The solid riveting process

Riveting is a joining method, by making a hole through two sheets and then passing a rivet to join them. When installing a solid rivet, access to both sides of the material is needed. Therefore, there is a “riveter” operator working on the outside with a rivet hammer, and a “bucker” operator on the other side with a bucking bar.

“You need a long experience to become a riveter”

Something that interested me from the research is that you are highly dependent on professional riveters. I found out that being a riveter is a special feeling you need to have since you hear and feel when the rivet is installed correctly. This is a feeling you get from long experience and mistakes.

The solid riveting process

Ideation

How can we make “dumb” tools smart?

I started to questioning, Instead of making new electric tools, how can we make the already existing pneumatic tools smart instead?

Concept Idea

After the research, I got an idea that I wanted to build my concept upon. Focusing on improving the human senses and experiences by having a smart system that can create signatures and identify changes in vibration and sound. The system is supposed to calculate "what is a bad and good installed rivet?" How does it vibrate in the material and how is the rivet hammer bouncing against the surface? The system is then connected to smart accessories, a toolbox, and a rivet hammer add-on. For further development on the design, I chose to only focus on the rivet hammer add-on.

Design Development

Building a rivet-hammer

Clay model of the rivet hammer add-on

Quick mock-ups

Testing size and ergonomics

Detail sketches

Using a 3D-scanner to get the real dimensions of the clay model

3D-printed and painted parts

Transfer the 3D-scanned object into CAD

CNC-milled mock-ups, testing size and details

Sketching on the last design refinements