Redesign of an original IR-thermometer

2 weeks project - MFA Umeå Institute of Design, 2019 - Individual project

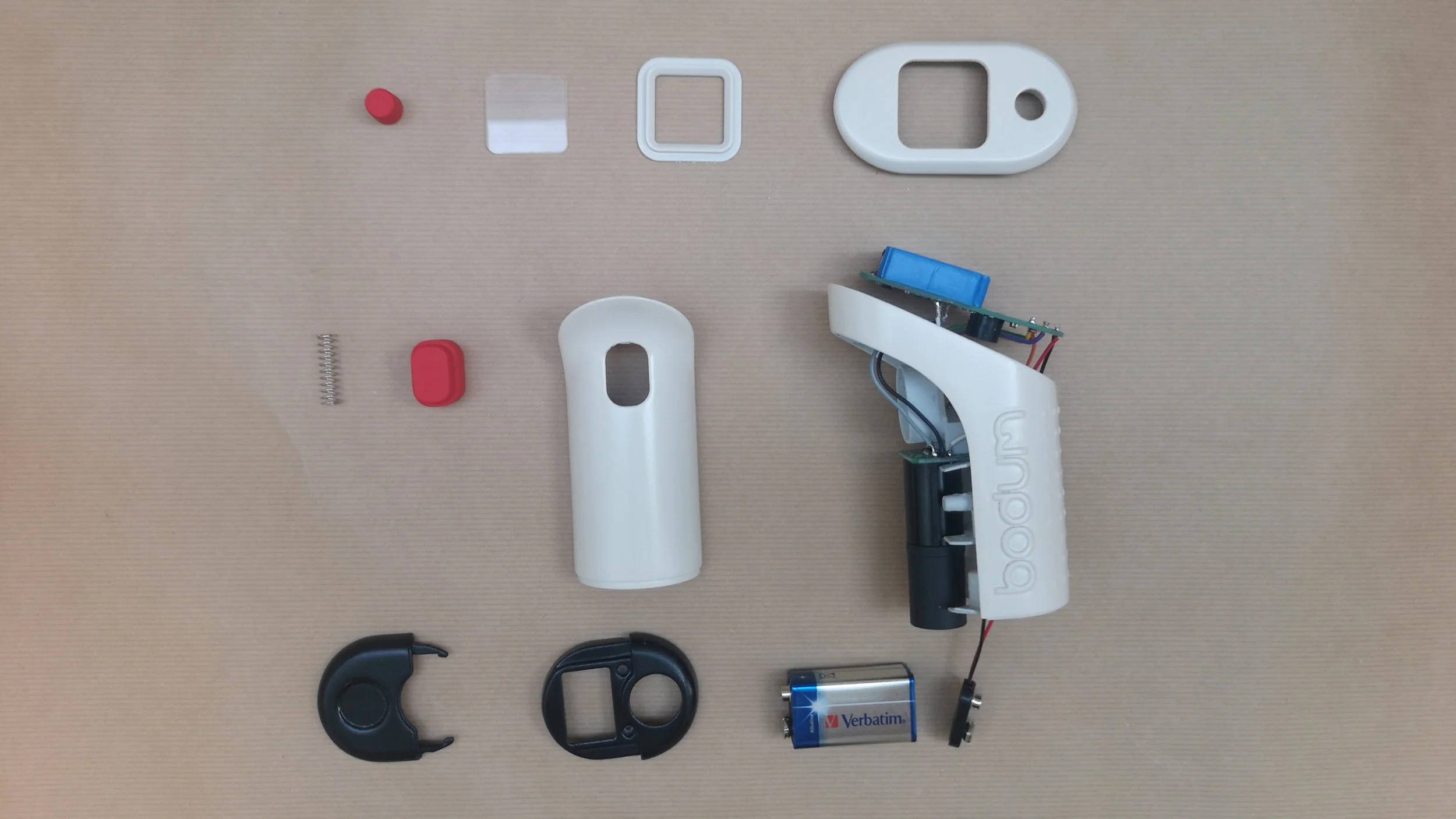

The purpose of the project was to learn about parametric modelling and production techniques. This by dismantling an existing IR-thermometer and placing the inner components into a new design with the outcome of a fully working prototype.

Starting point

Using the electronic components from an existing IR-thermometer

Design freeze in 20 hours

I wanted to design my thermometer for kitchen use and the brand Bodum, I created a brandboard for their design language to use as inspiration. I decided to rearrange the inner components to move away from the original pistol grip into a self-standing object instead. I used 2d sketching, 3d foam models and photoshop during the design phase, which was limited to 20 hours.

Building of the working prototype

During the project the production methods of the design had to be though-through and considered while I was building the CAD model. All the parts where then 3D-printed before I inserted the electronic components and finally painted and assembled the parts together into a fully working prototype.

CAD (Solid Works)

Soldering the electronic parts

3D - printing

Sanding

3D printed parts

Painting